With our huge inventory of new, used and rental equipment, WesTrac has the right machine for the job.

Cat Parts

Keep your operation working around the clock by making WesTrac your partner in parts. With over 75,000 product lines stocked in our warehouses, ready-to-go, we won't let you down.

WesTrac Services

With us in your corner, you won't just be hitting targets and meeting deadlines, you'll be achieving a higher standard of work, winning more business and delivering more value to your customers.

Technology Solutions

In today's world, you either harness technology or get left behind. Technology is what'll tip the scales to give your business an edge over your competitors.

SEARCH

Click anywhere to close

PRODUCTS

PARTS

SERVICES

TECHNOLOGY

Training

Company

News and Media

Online Tools

FitFleet Portal

Photo

Videos

360 View

- 360° View (HTML5)

Blades

BB121

Cat® Box Blades are designed for grading and leveling. Each model is designed to operate both manually and automatically with the use of Laser or GPS grading systems.

Request a quote

Overview

Cat® Box Blades are designed for grading and leveling of large commercial properties, housing pads, roadways, and parking lots and can operate both manually and automatically with the use of Laser or GPS grading systems. Developed to integrate with AccuGrade® electronic components it can achieve high levels of grading accuracy while increasing productivity and reducing operating costs. Designs for athletic fields, concrete prep, grading in buildings and tighter spaces, parking lots, back-filling can all be achieved with the Box Blade Attachment.

UNITS:

Metric

Imperial

| Overall Width | 2221 mm | 87.4 in |

| Working Width | 2131 mm | 83.9 in |

| Optimal Hydraulic Flow | 30-85 L/min (8-22 gpm) | 30-85 L/min (8-22 gpm) |

| Requires Full Work Tool Control with Both Joysticks | Yes | Yes |

| Optimal Hydraulic Pressure | 140-170 bar (2031-2466 psi) | 140-170 bar (2031-2466 psi) |

| Overall Length | 2062 mm | 81.2 in |

| Overall Height | 2694 mm | 106.1 in |

| Weight | 907 kg | 1999.6 lb |

| Tilt Angle Range +/- | 15 degrees | 15 degrees |

| Raise | 127 mm | 5 in |

| Lower | 102 mm | 4 in |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |

Features

Application

AccuGrade™ ready, the Box Blade is designed for grading and leveling of large commercial properties, housing pads, roadways, and parking lots.Curved Moldboards

Front and rear curved moldboards allow for material to roll and fold, improving capacity and performance. Flowing material will easily find low spots and improve grading and leveling performance.Wear Indicating Cutting Edges

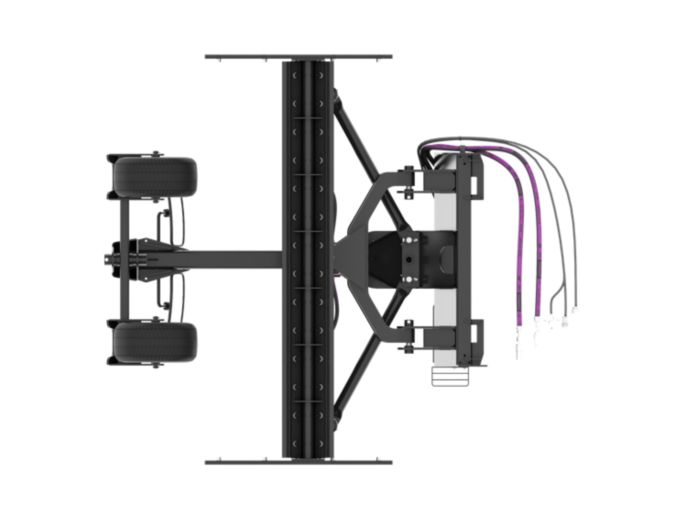

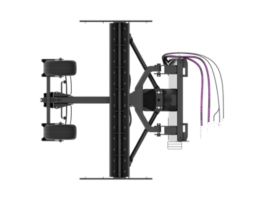

Wear indicating cutting edges feature 20% more wear material on the ground engaging section of the edge and also indicate when it is time to flip or replace the edge.Dual Parabolic Mirrors

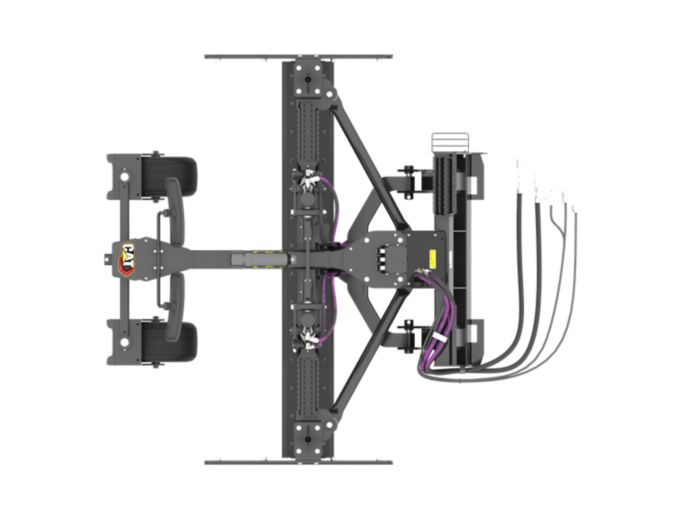

Dual parabolic mirrors provide full visibility to the front cutting edge allowing the operator to identify how much the blade is loading and see out to the corners of the Box Blade.Centrally Located Electronics

Technology components are centrally located and simply route to their respective harnesses back to this location on the tool. Then, a single harness routes to the control module in the cab or on the tool.Protected Hydraulic Valve and ECM

The hydraulic valve and ECM are enclosed and mounted within the frame of the tool, protected from damage.Dual Front Wheels

Dual front wheels are mounted on an independent axle and on casters to provide stability in both directions of travel. These wheels are air filled and will provide balance for the blade in both automatic and manual operation.Bolt-On Side Cutters and Wings

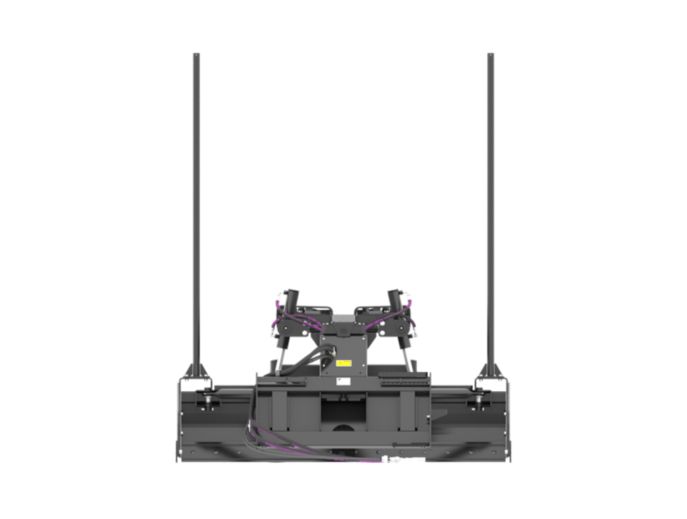

These improve the life of the tool with reversible side cutters and replaceable box wings. Both are bolt-on for simple replacement.Standard Fixed Masts

Standard fixed masts provide great performance for single or dual laser technology configurations as well as supporting 3D technology.Serrated Steps

Serrated bolt-on step provides safe ingress and egress from machine cab. Additional weld-on serrated steps on the blade ensure safe receiver adjustment, install, or removal.Tool Mounted Operation and Maintenance Manual Holder

Tool mounted and sealed from the elements, this holder includes all of the operation manuals and maintenance guides required for proper operation of the work tool.Downloads

Overview

Cat® Box Blades are designed for grading and leveling of large commercial properties, housing pads, roadways, and parking lots and can operate both manually and automatically with the use of Laser or GPS grading systems. Developed to integrate with AccuGrade® electronic components it can achieve high levels of grading accuracy while increasing productivity and reducing operating costs. Designs for athletic fields, concrete prep, grading in buildings and tighter spaces, parking lots, back-filling can all be achieved with the Box Blade Attachment.

UNITS:

Metric

Imperial

| Overall Width | 2221 mm | 87.4 in |

| Working Width | 2131 mm | 83.9 in |

| Optimal Hydraulic Flow | 30-85 L/min (8-22 gpm) | 30-85 L/min (8-22 gpm) |

| Requires Full Work Tool Control with Both Joysticks | Yes | Yes |

| Optimal Hydraulic Pressure | 140-170 bar (2031-2466 psi) | 140-170 bar (2031-2466 psi) |

| Overall Length | 2062 mm | 81.2 in |

| Overall Height | 2694 mm | 106.1 in |

| Weight | 907 kg | 1999.6 lb |

| Tilt Angle Range +/- | 15 degrees | 15 degrees |

| Raise | 127 mm | 5 in |

| Lower | 102 mm | 4 in |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |