With our huge inventory of new, used and rental equipment, WesTrac has the right machine for the job.

Cat Parts

Keep your operation working around the clock by making WesTrac your partner in parts. With over 75,000 product lines stocked in our warehouses, ready-to-go, we won't let you down.

WesTrac Services

With us in your corner, you won't just be hitting targets and meeting deadlines, you'll be achieving a higher standard of work, winning more business and delivering more value to your customers.

Technology Solutions

In today's world, you either harness technology or get left behind. Technology is what'll tip the scales to give your business an edge over your competitors.

SEARCH

Click anywhere to close

PRODUCTS

PARTS

SERVICES

TECHNOLOGY

Training

Company

News and Media

Online Tools

FitFleet Portal

Photo

Videos

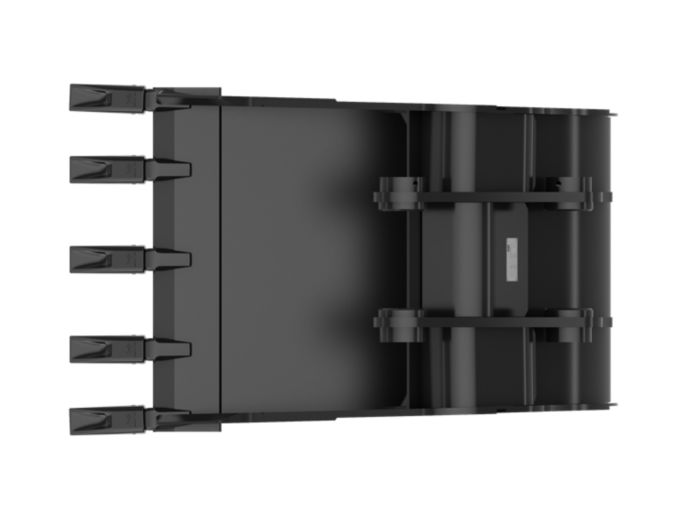

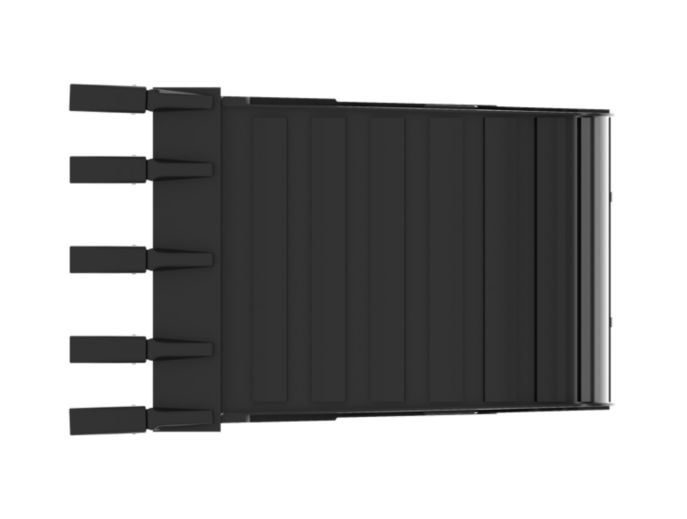

Buckets - Excavator

762 mm (30 in), Pin On

High strength buckets designed for maximum performance and value over a broad range of applications.

Request a quote

Overview

Heavy Duty Buckets for Cat® Mini Excavators are designed for maximum performance and value over a broad range of applications in abrasive applications such as mixed dirt, clay, and rock.

UNITS:

Metric

Imperial

| Width | 762 mm | 30 in |

| Capacity | 350 l | 12.4 ft³ |

| Weight | 257 kg | 566.6 lb |

| Base Edge Thickness | 25 mm | 1 in |

| Tip Radius | 1108 mm | 43.6 in |

| Interface Type | Pin On | Pin On |

Features

Application

Cat® Heavy Duty Buckets are well suited for semi-rocky soil or where hard bank material must be broken out and removed. Ideal for utility trenching, digging footings, back-filling and general excavating in construction, landscaping and utility applications.Bucket Design

Formed back wrapper design enhances bucket loading ability and production.Superior Bucket Fill

Optimum wrapper angle and no sharp corners promote superior bucket fill and reduce material packing.Bucket Shape

Enhanced bucket shape allows material to flow more easily. Tapered bucket sidewalls allow for easy dumping of sticky material.Overview

Heavy Duty Buckets for Cat® Mini Excavators are designed for maximum performance and value over a broad range of applications in abrasive applications such as mixed dirt, clay, and rock.

UNITS:

Metric

Imperial

| Width | 762 mm | 30 in |

| Capacity | 350 l | 12.4 ft³ |

| Weight | 257 kg | 566.6 lb |

| Base Edge Thickness | 25 mm | 1 in |

| Tip Radius | 1108 mm | 43.6 in |

| Interface Type | Pin On | Pin On |