With our huge inventory of new, used and rental equipment, WesTrac has the right machine for the job.

Cat Parts

Keep your operation working around the clock by making WesTrac your partner in parts. With over 75,000 product lines stocked in our warehouses, ready-to-go, we won't let you down.

WesTrac Services

With us in your corner, you won't just be hitting targets and meeting deadlines, you'll be achieving a higher standard of work, winning more business and delivering more value to your customers.

Technology Solutions

In today's world, you either harness technology or get left behind. Technology is what'll tip the scales to give your business an edge over your competitors.

SEARCH

Click anywhere to close

PRODUCTS

PARTS

SERVICES

TECHNOLOGY

Training

Company

News and Media

Online Tools

FitFleet Portal

Photo

Videos

360 View

- 360° View (HTML5)

Overview

Cat® Hammers for Skid Steer Loaders, Compact Track Loaders, Mini Excavators and Backhoe Loaders are high performance breakers, designed for maximum performance on demolition, construction, and road work.

UNITS:

Metric

Imperial

| Operating Weight - With Tool | 627 kg | 1382.3 lb |

| Energy Class | 2034 J | 1500.2 ft·lbf |

| Machine Class | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (No Side Shift) | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (No Side Shift) |

| Tool Shaft Diameter | 87.5 mm | 3.4 in |

| Impact Frequency | 700-1260 bpm | 700-1260 bpm |

| Minimum Operating Pressure | 10000 kPa | 1450.4 psi |

| Minimum Carrier Weight | 6985 kg | 15399.3 lb |

| Optimal Hydraulic Flow | 70-150 lpm (18-40 gpm) | 70-150 lpm (18-40 gpm) |

| Overall Width | 512 mm | 20.2 in |

| Overall Length | 520 mm | 20.5 in |

| Overall Height | 1666 mm | 65.6 in |

| Height - Without Tool | 1250 mm | 49.2 in |

| Sound Level | 124 dB | 124 dB |

| Mounting Bracket Size | Extra Large | Extra Large |

Features

Application

Used in a wide range of construction and light demolition applications - such as breaking concrete sidewalks and driveways, pavement, roads, masonry, site prep and landscaping, and breaking frozen ground for utility repairs.Silenced

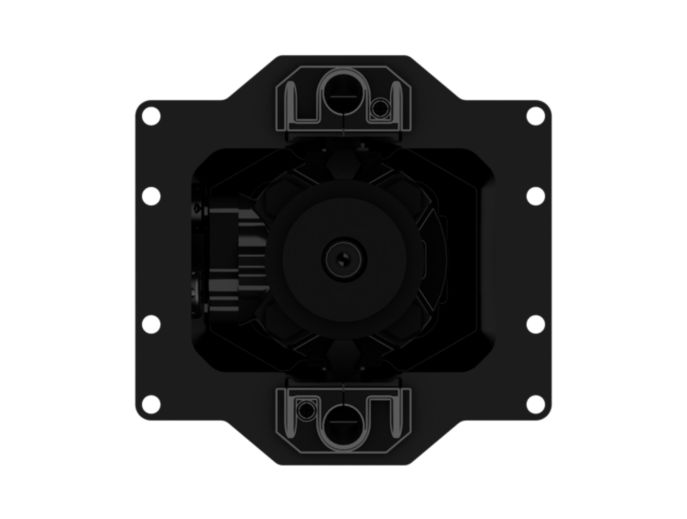

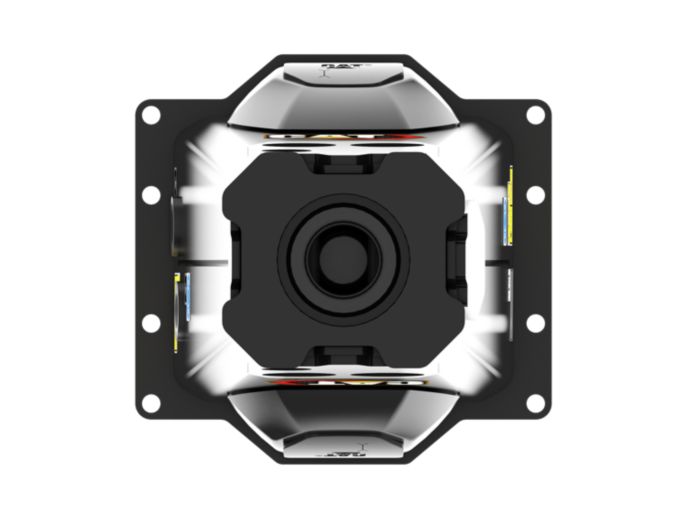

Fully enclosed, silenced housing lowers overall noise level for a quieter, safer job site. Internal power cell is protected, designed and engineered to eliminate stress points.Flat Top/Top-Mount Style

Flat top/top-mount style provides a larger work area and excellent operator visibility with a common footprint and hole pattern for optimum versatility. Top-mount style increases impact power by keeping breaker force and stick force in line. A top-mount bracket will transfer back significantly less recoil and bending stress into the end of the stick, resulting in reduced impact on machine structures. Full complement of mounting brackets is available to suite coupler or pin-on preference.Auto Shut Off (ASO)

ASO instantly stops the piston when breaking through material, preventing blank firing, a key contributor to hammer wear. Internal stresses are reduced, hammer is protected regardless of operator skill level.Tri-Suspension System

Tri-Suspension system comprises the suspension jacket, the upper and lower buffers. Suspension aligns power cell and gives manageable, smooth performance.Standing Height Grease Point

Standing height grease point makes required maintenance comfortable and easy to perform.Easy to Tune & Maintain

Gas ports and valves are easy to check and charge while hammer is mounted to machine.Ports Positioned for Hose Protection

Improved routing protects against force and dirt during impact, eliminating downtime.Hammer Tools

Tools are heat-treated, matched to piston diameter and provide optimum mass to deliver full blow energy.Overview

Cat® Hammers for Skid Steer Loaders, Compact Track Loaders, Mini Excavators and Backhoe Loaders are high performance breakers, designed for maximum performance on demolition, construction, and road work.

UNITS:

Metric

Imperial

| Operating Weight - With Tool | 627 kg | 1382.3 lb |

| Energy Class | 2034 J | 1500.2 ft·lbf |

| Machine Class | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (No Side Shift) | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (No Side Shift) |

| Tool Shaft Diameter | 87.5 mm | 3.4 in |

| Impact Frequency | 700-1260 bpm | 700-1260 bpm |

| Minimum Operating Pressure | 10000 kPa | 1450.4 psi |

| Minimum Carrier Weight | 6985 kg | 15399.3 lb |

| Optimal Hydraulic Flow | 70-150 lpm (18-40 gpm) | 70-150 lpm (18-40 gpm) |

| Overall Width | 512 mm | 20.2 in |

| Overall Length | 520 mm | 20.5 in |

| Overall Height | 1666 mm | 65.6 in |

| Height - Without Tool | 1250 mm | 49.2 in |

| Sound Level | 124 dB | 124 dB |

| Mounting Bracket Size | Extra Large | Extra Large |