With our huge inventory of new, used and rental equipment, WesTrac has the right machine for the job.

Cat Parts

Keep your operation working around the clock by making WesTrac your partner in parts. With over 75,000 product lines stocked in our warehouses, ready-to-go, we won't let you down.

WesTrac Services

With us in your corner, you won't just be hitting targets and meeting deadlines, you'll be achieving a higher standard of work, winning more business and delivering more value to your customers.

Technology Solutions

In today's world, you either harness technology or get left behind. Technology is what'll tip the scales to give your business an edge over your competitors.

SEARCH

Click anywhere to close

PRODUCTS

PARTS

SERVICES

TECHNOLOGY

Training

Company

News and Media

Online Tools

FitFleet Portal

Photo

Videos

360 View

- 360° View (HTML5)

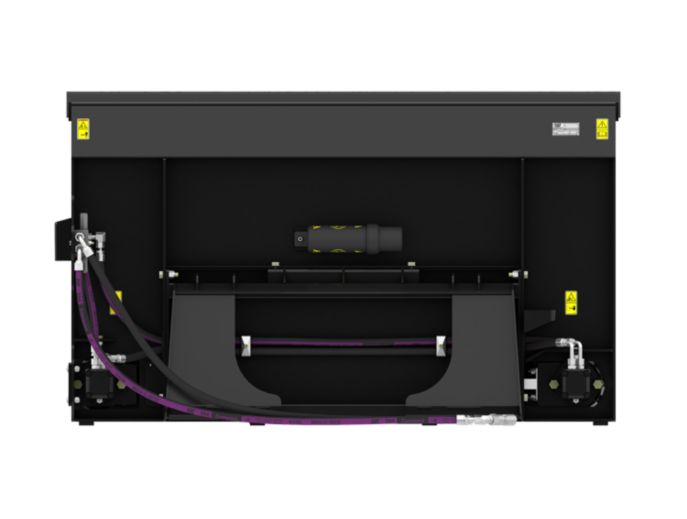

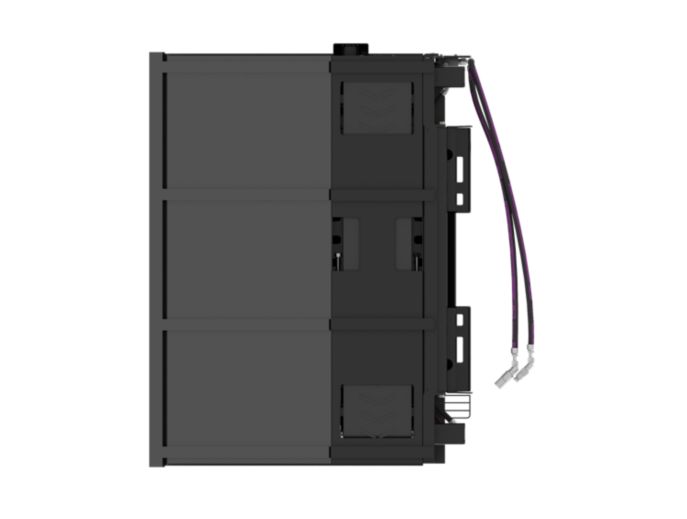

Buckets - Skid Steer Loader

BD118 Sawdust

Collect and discharge sawdust, mulch, straw and sand into barns, stalls and orchards, backfill top soil or pea gravel into trenches and spread silage.

Request a quote

Overview

Cat® Side Discharge Buckets for Cat Skid Steer Loaders, Compact Track Loaders and Compact Wheel Loaders are designed to handle a variety of material management and aggregate distribution needs. The left or right discharge design eliminates the need for awkward maneuvering, saving time. Spread material in forward or reverse, left or right and get into the tightest areas of your operation.

UNITS:

Metric

Imperial

| Capacity | 1.53 m³ | 2 yd³ |

| Width | 1860 mm | 73.2 in |

| Required Hydraulics | Standard Flow | Standard Flow |

| Weight | 535 kg | 1179.5 lb |

| Height | 1118 mm | 44 in |

| Length | 1451 mm | 57.1 in |

| Optimal Hydraulic Flow | 76-87 lpm (20-23 gpm) | 76-87 lpm (20-23 gpm) |

| Optimal Hydraulic Pressure | 130-230 bar (2000-3300 psi) | 130-230 bar (2000-3300 psi) |

| Belt Width | 305 mm | 12 in |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |

| Overall Width | 1900 mm | 74.8 in |

Features

Application

Designed to collect and discharge sawdust, mulch, straw and sand into barns, stalls and orchards, backfill top soil or pea gravel into trenches and spread silage.Manually Adjustable Discharge Doors

Manually adjustable discharge doors on both sides regulate the volume of discharged material. Thick plating reinforces the doors for long lasting performance.Dual Direction Rubber Conveyor Belt

Dual direction rubber conveyor belt is heavy-duty with a raised chevron tread and adjustable tension belt. Dual direction drive boosts productivity by eliminating the need for awkward maneuvering commonly encountered in tight areas.High Torque Agitator

High torque agitator assembly is directly powered by an independent hydraulic motor. Motor and conveyor systems rotate in conjunction on bi-axis planes for consistent flow and to prevent material from bridging inside the bucket.Dual Direct Drive Hydraulic Motors

Dual direct drive hydraulic motors drive the belt and a third motor drives the agitator providing consistent hydraulic flow. Motors are externally mounted for convenient access.Welded-On Serrated Safety Step

Welded-on serrated safety step allows for easy entry and exit from the cab.Tool Mounted Operation and Maintenance Manual

Tool mounted operation and maintenance manual required for proper operation of the work tool attachment is sealed from the elements.Overview

Cat® Side Discharge Buckets for Cat Skid Steer Loaders, Compact Track Loaders and Compact Wheel Loaders are designed to handle a variety of material management and aggregate distribution needs. The left or right discharge design eliminates the need for awkward maneuvering, saving time. Spread material in forward or reverse, left or right and get into the tightest areas of your operation.

UNITS:

Metric

Imperial

| Capacity | 1.53 m³ | 2 yd³ |

| Width | 1860 mm | 73.2 in |

| Required Hydraulics | Standard Flow | Standard Flow |

| Weight | 535 kg | 1179.5 lb |

| Height | 1118 mm | 44 in |

| Length | 1451 mm | 57.1 in |

| Optimal Hydraulic Flow | 76-87 lpm (20-23 gpm) | 76-87 lpm (20-23 gpm) |

| Optimal Hydraulic Pressure | 130-230 bar (2000-3300 psi) | 130-230 bar (2000-3300 psi) |

| Belt Width | 305 mm | 12 in |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |

| Overall Width | 1900 mm | 74.8 in |