With our huge inventory of new, used and rental equipment, WesTrac has the right machine for the job.

Cat Parts

Keep your operation working around the clock by making WesTrac your partner in parts. With over 75,000 product lines stocked in our warehouses, ready-to-go, we won't let you down.

WesTrac Services

With us in your corner, you won't just be hitting targets and meeting deadlines, you'll be achieving a higher standard of work, winning more business and delivering more value to your customers.

Technology Solutions

In today's world, you either harness technology or get left behind. Technology is what'll tip the scales to give your business an edge over your competitors.

SEARCH

Click anywhere to close

PRODUCTS

PARTS

SERVICES

TECHNOLOGY

Training

Company

News and Media

Online Tools

FitFleet Portal

Photo

Videos

Nursery Products

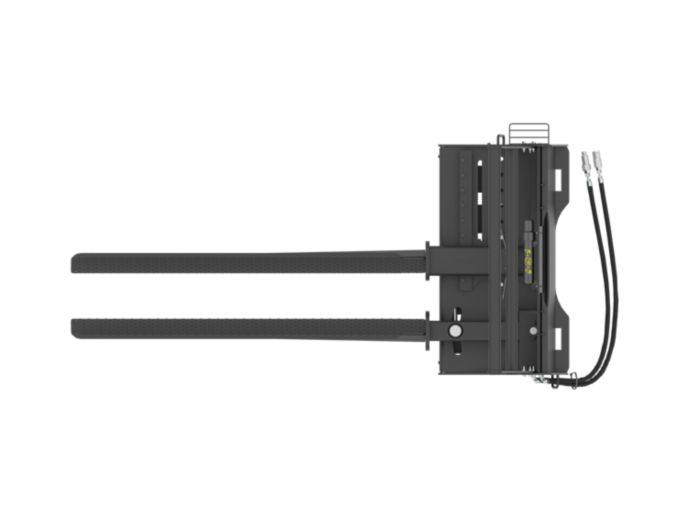

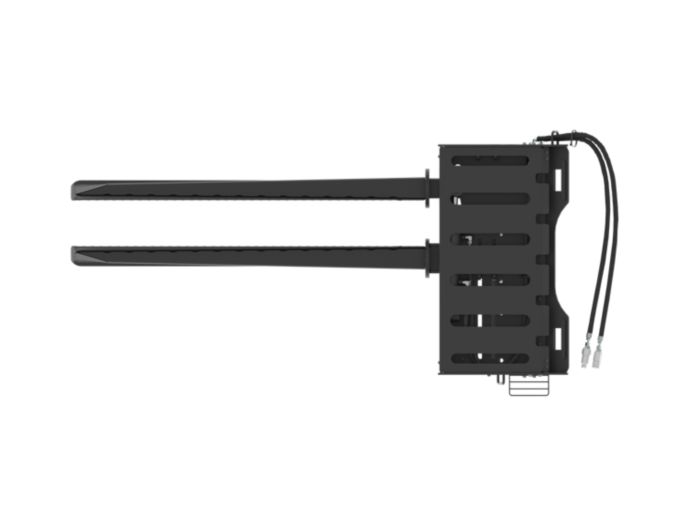

Manual Nursery Fork

Nursery Forks are used to move ball and burlap trees, as well as potted plants in nursery and landscaping applications.

Request a quote

Overview

Cat® Nursery forks for Compact Wheel loaders, Compact Track Loaders, and Skid Steer Loaders are designed to allow pivoting one fork out for gained maneuverability and handling capabilities in nursery and landscaping applications. Fork tines can be configured with a manually adjusted fork or hydraulically side shifting fork to give greater flexibility when handling multiple or different sized root balls.

UNITS:

Metric

Imperial

| Overall Length | 2491 mm | 98.1 in |

| Overall Width | 1327 mm | 52.2 in |

| Weight | 342 kg | 754 lb |

| Overall Height | 1427 mm | 56.2 in |

| Usable Tine Length | 1788 mm | 70.4 in |

| Length Between Adjustments | 79 mm (3.1 in) | 79 mm (3.1 in) |

| Number of Adjustments | 6 | 6 |

| Total Tine Movement | 393 mm | 15.5 in |

| Angled Tine Opening Minimum at Tip | 48.1 mm | 1.9 in |

| Angled Tine Opening Maximum at Tip | 1196 mm | 47.1 in |

| Parallel Tine Opening Minimum | 225 mm | 8.9 in |

| Parallel Tine Opening Maximum | 617 mm | 24.3 in |

| Maximum Root Ball Diameter | 1372 mm | 54 in |

| Maximum Lifting Capacity | 1361 kg | 3000 lb |

| Optimal Hydraulic Flow | 49-87 lpm (12-23 gpm) | 49-87 lpm (12-23 gpm) |

| Optimal Hydraulic Pressure | 170-241 bar (2500-3500 psi) | 170-241 bar (2500-3500 psi) |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |

| Required Hydraulics | Standard Flow | Standard Flow |

Features

Side Shifting Right Fork

Allows for greater control and maximizes proper fit when handling different sized root balls.Pivoting Left Fork

Pivoting fork allows maximum opening to grasp larger root balls.Diamond Tread Plate

Provides a secure grip on the load for maximum load retention. Fork angles at 25 degrees to closely match the standard angle on most root balls.Grab Handle

Integrated grab handle allows a secure contact point upon entry/exit of the machine for the operator.Serrated Step

Deeply serrated step provides secure footing for operators entering and exiting machines.Operation Maintenance Manual Container

Tool mounted and sealed from the elements, this holder includes all the operation manuals and maintenance guides required for proper operation of the tool.Downloads

Overview

Cat® Nursery forks for Compact Wheel loaders, Compact Track Loaders, and Skid Steer Loaders are designed to allow pivoting one fork out for gained maneuverability and handling capabilities in nursery and landscaping applications. Fork tines can be configured with a manually adjusted fork or hydraulically side shifting fork to give greater flexibility when handling multiple or different sized root balls.

UNITS:

Metric

Imperial

| Overall Length | 2491 mm | 98.1 in |

| Overall Width | 1327 mm | 52.2 in |

| Weight | 342 kg | 754 lb |

| Overall Height | 1427 mm | 56.2 in |

| Usable Tine Length | 1788 mm | 70.4 in |

| Length Between Adjustments | 79 mm (3.1 in) | 79 mm (3.1 in) |

| Number of Adjustments | 6 | 6 |

| Total Tine Movement | 393 mm | 15.5 in |

| Angled Tine Opening Minimum at Tip | 48.1 mm | 1.9 in |

| Angled Tine Opening Maximum at Tip | 1196 mm | 47.1 in |

| Parallel Tine Opening Minimum | 225 mm | 8.9 in |

| Parallel Tine Opening Maximum | 617 mm | 24.3 in |

| Maximum Root Ball Diameter | 1372 mm | 54 in |

| Maximum Lifting Capacity | 1361 kg | 3000 lb |

| Optimal Hydraulic Flow | 49-87 lpm (12-23 gpm) | 49-87 lpm (12-23 gpm) |

| Optimal Hydraulic Pressure | 170-241 bar (2500-3500 psi) | 170-241 bar (2500-3500 psi) |

| Interface Type | Skid Steer Coupler | Skid Steer Coupler |

| Required Hydraulics | Standard Flow | Standard Flow |